Despite its presence as a pillar of modern manufacturing, lathes have existed for thousands of years. The power and ease of use have both benefitted from technology upgrades but improvements to safety are most prominent.

Smoothing out the torque of a lathe, even when shaping dense materials pales in comparison to these safety advancements. A good electronic lathe brake interrupts rotation in less than a fraction of a second.

Since lathes top out over 2000 rpm, they need this power and precision to prevent and limit injury.

Learn how a lathe brake works and what you need to know about maintaining them below.

Types of Lathe Brakes

While a brake on a lathe works to stop the machine from turning, not all brakes function the same way. Modern lathes contain multiple types of brakes to provide longevity to the machine and to perform under different conditions.

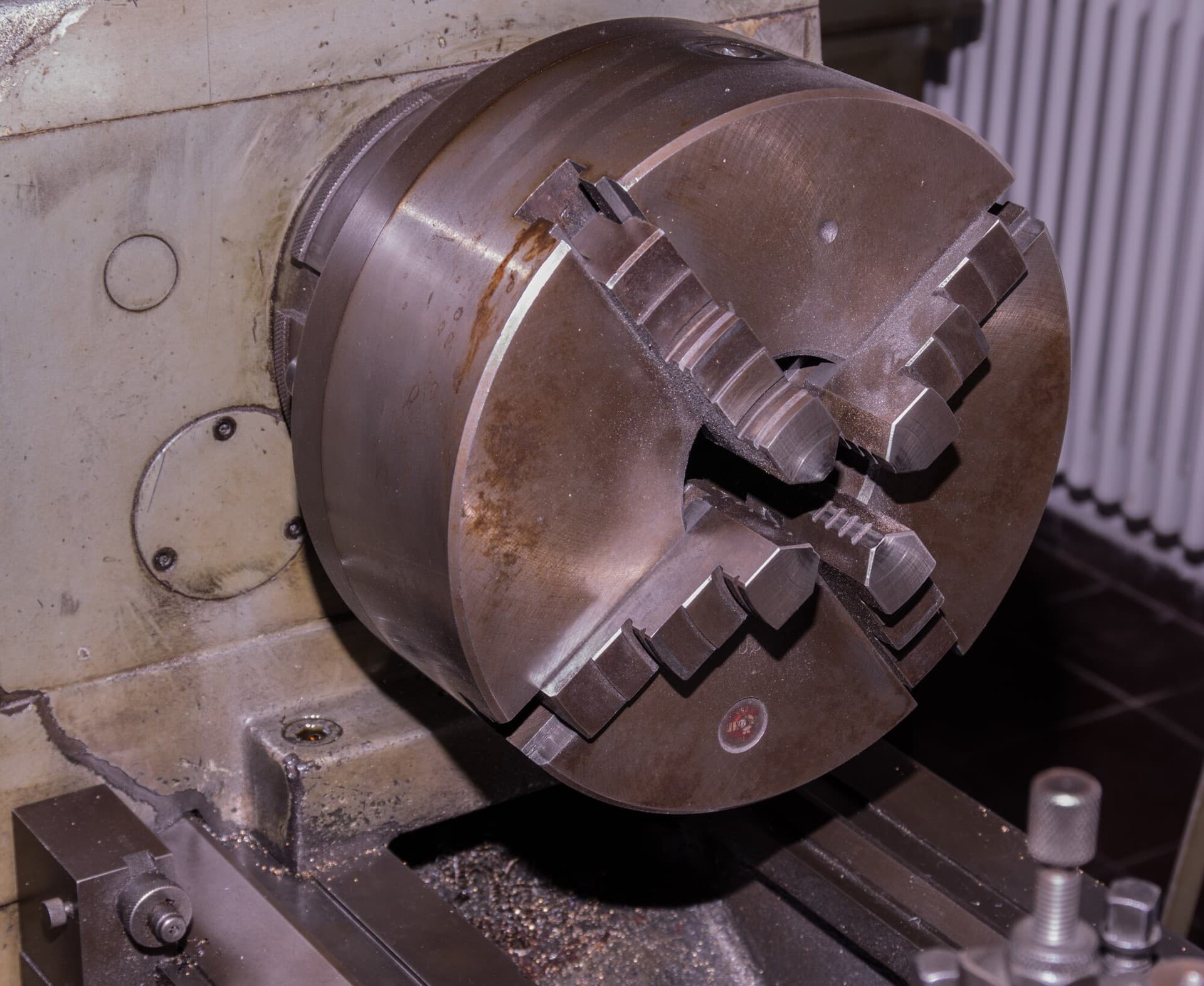

A lathe rotates quickly and provides enough torque to withstand the drag forces of tools against the material being shaped. this means a lathe has a lot of physical force in play.

Stopping that force isn’t easy, not just from the perspective of the time and energy but also to avoid causing damage to the machine and materials being worked. If a lathe stops unevenly, the material held between the spindle and the tailstock may buckle.

Sudden mechanical stops of the rotational motor also could strip important components, rendering the machine nonfunctional.

Lathe brakes need to account for these results and counter them.

Headstock

The motor powering the machine is held inside the headstock assembly. Brakes on the motor are commonly electronic motor brakes. These work by either locking in place when a current is applied or releasing when a current is applied.

DC injection braking holds the rotor of the motor in place. This happens within a single turn of the rotor and uses the same electromotive force the motor uses to turn. DC motor brakes don’t have to stop immediately but can disengage forward momentum and allow for a lathe to stop gradually.

Dynamic braking applies an alternative engine to the rotor, pulling it in the other direction. This stops the motor immediately and counters for the balance of the load.

Both of these types of brakes stop motion with the motor and can engage and disengage without causing damage to the motor.

Foot Brake

A foot brake stops the load and the motor. Foot brakes engage mechanical and electronic brakes.

The end result is an instant stop but it comes at a price of wear on the mechanical elements. A foot brake disengages tools from the material at the same time that it spots the spindle. This limits points of damage to the material and splinters and shards from being formed as it stops.

Stop Safely

Investing in an electronic lathe brake ensures safety to workers and longevity to machinery.

Safety measures need to extend to all of the elements in a situation. When a lathe brake acts to protect workers and the machine itself it fulfills this need.

for more information about our line of electric motor brakes, contact us.