How Does a Motor Brake Work?

As hard as it is to get something moving, getting [...]

5 Top Tips for Selecting DC Motor Brakes

In a world of 'just enough' finding 'just right' is [...]

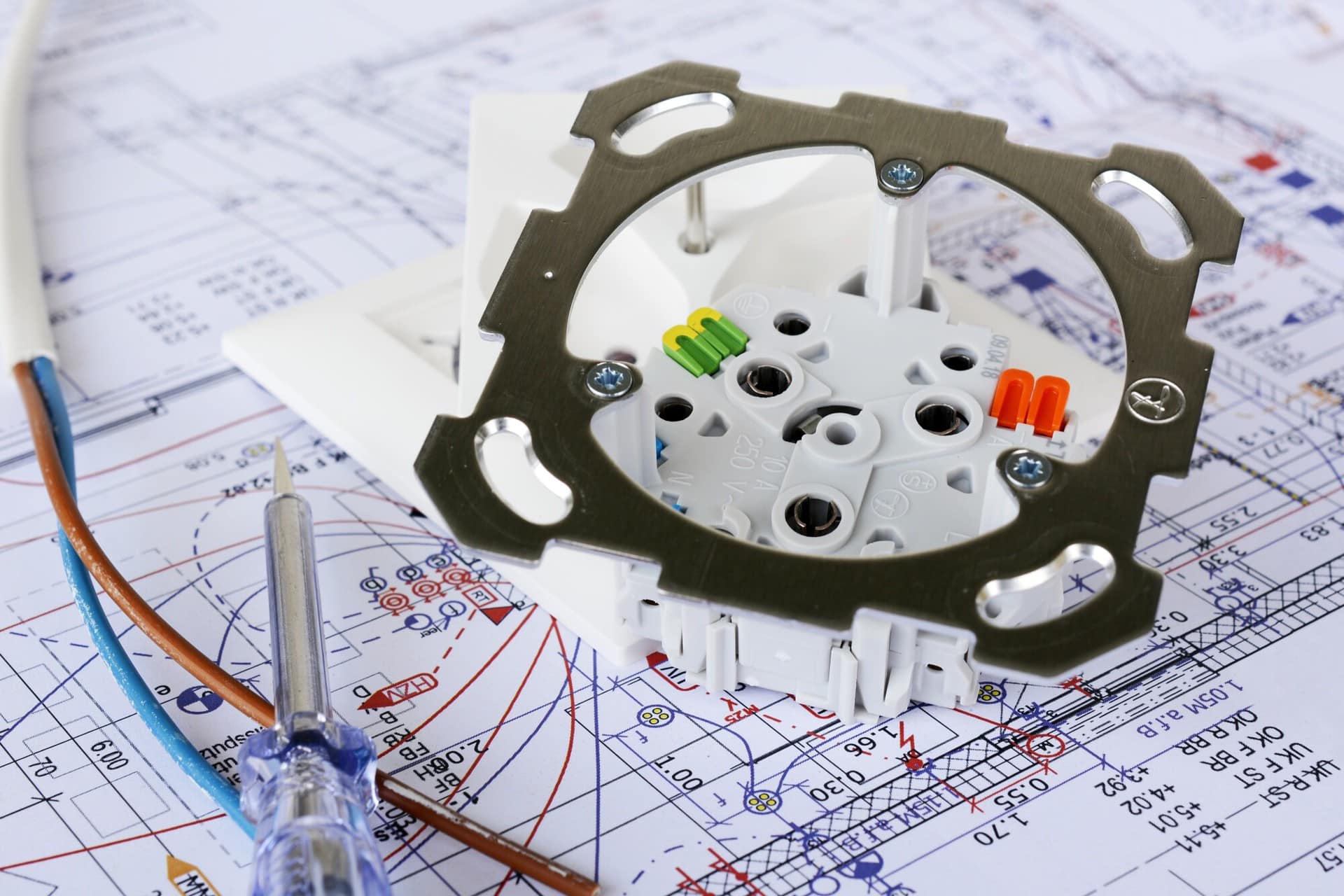

Electric Motor Uses and Maintenance: Choosing the Right Motor For You

Are you looking for an electric motor, but you don't [...]

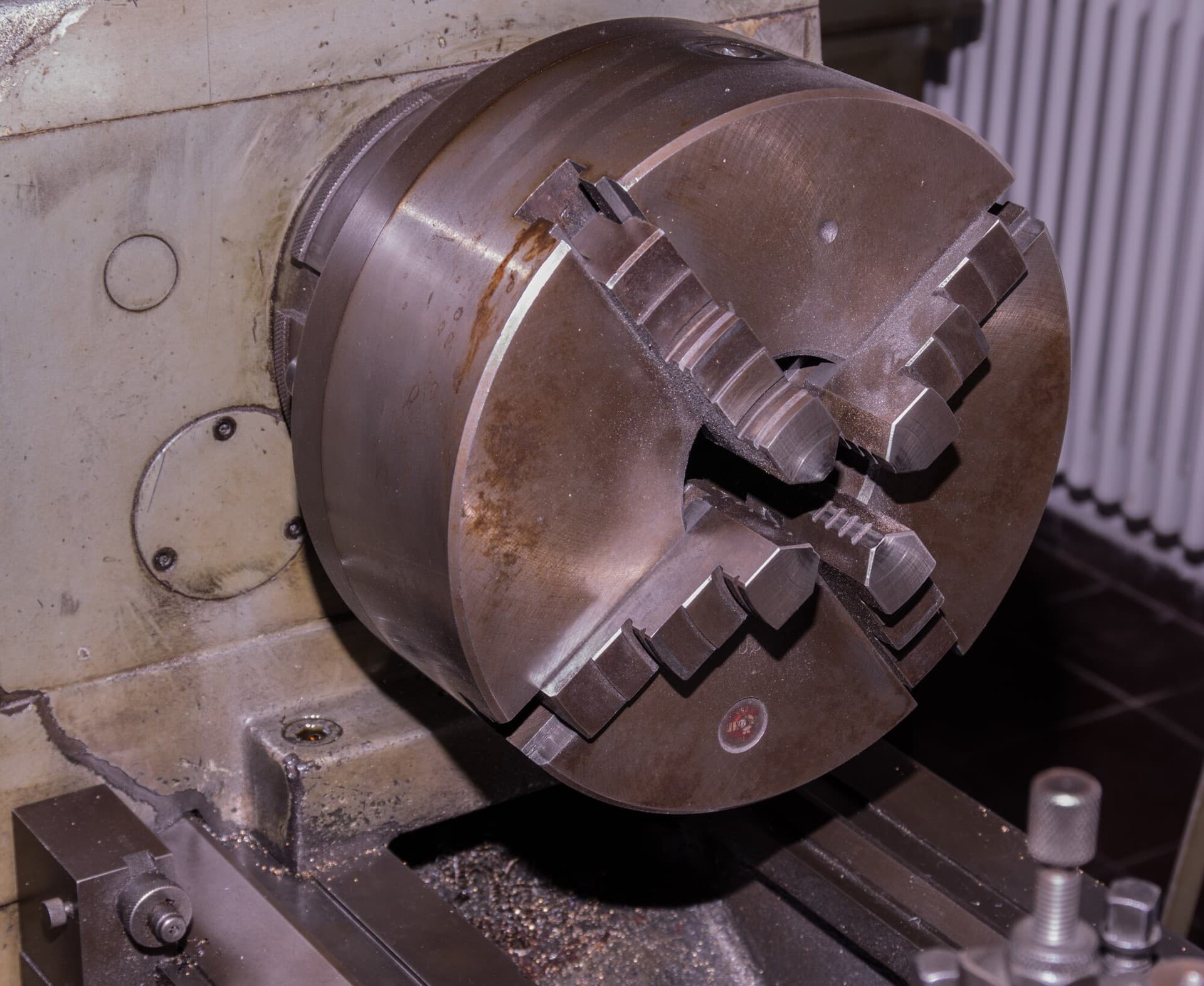

A Simple Guide to Lathe Brakes

Despite its presence as a pillar of modern manufacturing, lathes [...]

How to Service Your Motor Brakes

Motor brakes are one of the most useful parts of [...]

The Electric Motor Invention and Where We Are Today

Did you know that the Electric Motor Market is projected [...]