In your machine shop, time is money. The less time it takes to complete your daily production tasks, the more money you can make. The problem is, you’ve noticed lately that bottlenecks are causing your productivity to take a dive.

The reality is, machine shops took a hit when the COVID-19 pandemic struck the United States. However, manufacturing businesses have since reopened and are adjusting to the “new normal.” That means now, it’s critical that you keep your shop running like a dream to stay ahead of your competition.

Fortunately, little improvements can result in big increases in productivity over time. Here’s a rundown on how to make your machine shop run more smoothly in 2021 and beyond.

Let’s jump in!

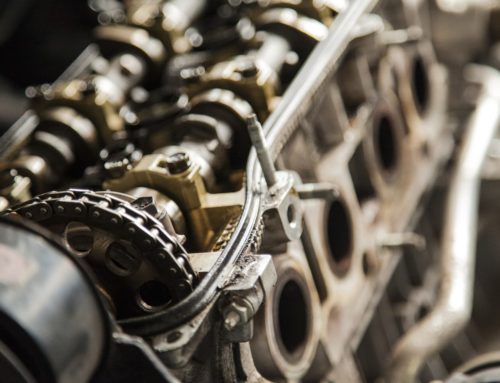

Take Advantage of Routine Maintenance

An important step in boosting your machine shop productivity is to perform routine maintenance on your shop’s equipment.

Why? Because performing preventative maintenance can improve your equipment’s lifespan. This will reduce your chances of experiencing a machine malfunction or breakdown.

In fact, you may want to install smart machines in your shop, as today’s smart machines can actually diagnose themselves. As a result, the equipment can shut itself down during emergencies.

Smart machines will decrease your workers’ chances of suffering injuries. They will also prevent hardware damage. This will decrease your likelihood of experiencing downtime, which will cost you time and money.

Get Your Machine Shop Organized

Consider also organizing your shop to make it more productive.

Industrial totes are particularly helpful for organizing your machine shop’s smaller tools. That’s because their plastic surfaces can easily be cleaned. In addition, they are durable and reusable.

If possible, you should involve your staff in the shop organization process. They may offer some renovation or redesign feedback to further improve your workplace’s productivity. And you may improve your employee relationships in the process.

Use Electronic Brakes

Consider also replacing your mechanical brakes with modern electronic ones to improve your shop’s productivity.

Electronic brakes are able to force a high-inertia load to a full stop by utilizing electromagnetic forces. This means you can quickly stop and start your equipment, which will make your machine shop more efficient and productive.

Electronic brakes also are low maintenance. In addition, they can promote better worker safety in various applications in your shop.

How We Can Help

We are a leading provider of electronic motor brakes, which can come in handy in thousands of machine shop applications. Our brakes can easily, quickly, and permanently replace their mechanical brake counterparts this spring season.

As we are among the first electronic motor brake manufacturers in the United States, we stand out for reliability and quality across the industry. All of our brakes offer maintenance-free and safe operation, which is why our customers love them.

Contact us to discover more about how our brakes can make your machine shop more productive in the months and years ahead.