Stop the machine! Emergency! This is the time when you need an electric motor brake! In an emergency, you cannot let the motor stop naturally. It just takes too long.

Today, machinery is moving faster and faster, and there is a demand for more start and stops. Thus, it is imperative to have the right electric motor brake to match the equipment used.

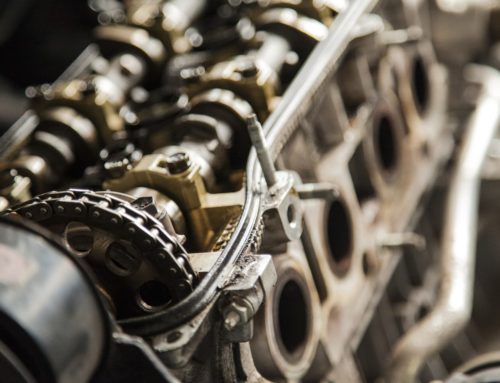

There are many different types of motor brakes. Lifting heavy-duty loads, cranes, saws, grinders, conveyors, lathes, and more are some of the uses of electric motor brakes.

Buying the right kind of brake is critical to your safety and the safety of your workers. Here is help on how to choose your type of electric motor brake.

What Is an Electric Motor Brake

Electric motor brakes are apparatus that uses electric current to stop or slow down the motion of a turning part of a machine. They are used in machine braking applications that need rapid response time and exact tension control.

The electric motor brake uses friction between two surfaces to stop and hold a load. It is important to make sure that the brake has enough torque power to stop within the allocated time.

Most Commonly Used Motor Brakes

Three of the most commonly used types of brakes are DC brakes, three-phase brakes, and single-phase solenoid or linkage brakes, although there are other types available.

DC Brakes

DC brakes use springs to exert a force against the armature plate. It squeezes the friction disk between the framework plate and the mounting plate.

The hub creates a braking torque and is attached to the shaft of the motor. By giving the coil energy makes the armature plate attracted to it. Thus this releases the friction disk to rotate with the hub and motor shaft. Dc brakes also feature a manual release handle and adjustable torque.

Three-Phase Brakes

Three-phase brakes work very similar to DC brakes. They use an electric coil to generate a magnetic field to bring the braking armature back to position.

The torque in a three-phase braking system is adjustable but is not as responsive as a DC brake.

Single Phase or Linkage brakes

There is a slight difference in the design for single-phase or linkage brakes. They use a linear solenoid to pull a mechanical linkage which releases pressure springs and then pulls up the pressure plate. Once the pressure plate is up, the disk can rotate without hindrance.

The torque in the single-phase linkage brake cannot be adjusted.

The drawback of this type of brake is the wear and tear the moving parts will take. These brakes should not be used for exact stopping applications.

Things to Consider When Selecting a Motor Brake

When selecting an electric motor brake, there are several things to take into consideration.

Torque and Revolutions per minute (RPM) are the two most obvious. The cycle rate and available power supply also play a big part in the choice of electric motor brake to choose.

Last but not least, ergonomics such as space, mounting, and accessibility also have to be considered.

Stop! Choose Right

Do your research when choosing an electric motor brake. For example, an electric motor brake used in surgical theaters where the noise level is of concern will differ from a lathe used in your garage!

If you are in doubt about what electric motor brake is right for you, contact us, and we will be glad to help!